Published on: April 1, 2022

The concept of Industry 4.0- was coined to describe the phenomenon for merging of real and virtual worlds based on Cyber Physical Production Systems (CPPS).

It was evolved way back in 1960-70 aimed at enhancement of productivity of manufacturing organizations. Today Industry 4.0 is the current trend of automation technologies used for creating a smart factory. The figure below shows few components of Industry 4.0. Through these technologies we integrate different departments of the manufacturing companies to streamline their manufacturing operations.

Applications of Industry 4.0 in the manufacturing sector as implemented by ecubix. Ecubix inducts Industry 4.0 solution platform which provides:

A. Real-time information regarding the whole manufacturing process. The visibility thus created throughout the value chain allows optimization in:

- Raw material used in production,

- Logistics in the supply of the materials through different stages

- Origin of the material and it’s quality parameters

- Different activities associated with the production like improving production rate. Or in total quality management. Directly impacting OEE of the organization.

Thus, distribution of resources and goods can be controlled effectively to manage the production activities effectively.

B. Next is bringing the risks of surplus production and the wastage of resources for surplus production in front. Implementation of Industry 4.0 is very much important for managing an end-to-end digital supply chain.

C. Provide data to organization in a contextualized form. This enhances the usage of data it’s understanding leading to improvement in the productivity of the workers.

D. Next is validity of the data. Generally, when data is used to create predictive models or applying AI to them 80% of the data analyst team gets used up in data massaging. The platform provided by ecubix provides a pre-validated data which makes it ripe to be instantly fed to AI tools.

E. Once validated data is available, we need to analyze the data using various statistical formulae. The platform has pre-embedded formulae or algorithms in it. What more it allows additional analytical tools to be embedded in it. Thus, it enables the stake holders specializing in their area of expertise to play with the data and freely come out with numerous efficiencies creating use cases. Our platform is completely free from coding needs.

F. Last but the most important part of any data integrating platform is its ability to provide visualization of such a nature that it enables the users to get a constant stream of decision enabling visual form which provides a near instant root cause analysis and an ability to simplify the processes in a manner where the operating team is able to take corrective action before any issue creates a loss making preposition.

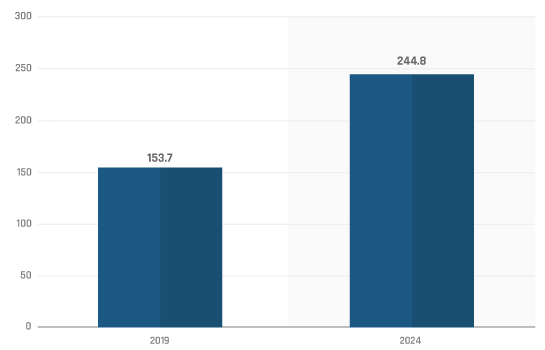

Adoption of Industry 4.0 and IoT-based automation technology in the manufacturing sector Though many of large manufacturing organizations have shown interest to implement Industry 4.0. But after the pandemic the need of this has become a key reason for their success. Estimate shows by 2024 the organizations opting for the solution is expected to grow by 70%.

However, SMEs face different types of challenges in the implementation of Industry 4.0. The common issues being lack of talent and technical skills and the lack of resources and funds for implementing those automation technologies. However, ecubix has such unique process of implementing the solution that instantly within a period of three to four months organizations are able to realize cost savings to the tune that returns of their investment happens very fast. Before implementation the pilot evolves the system in such a manner that it is the operator level who grab the learnings first.