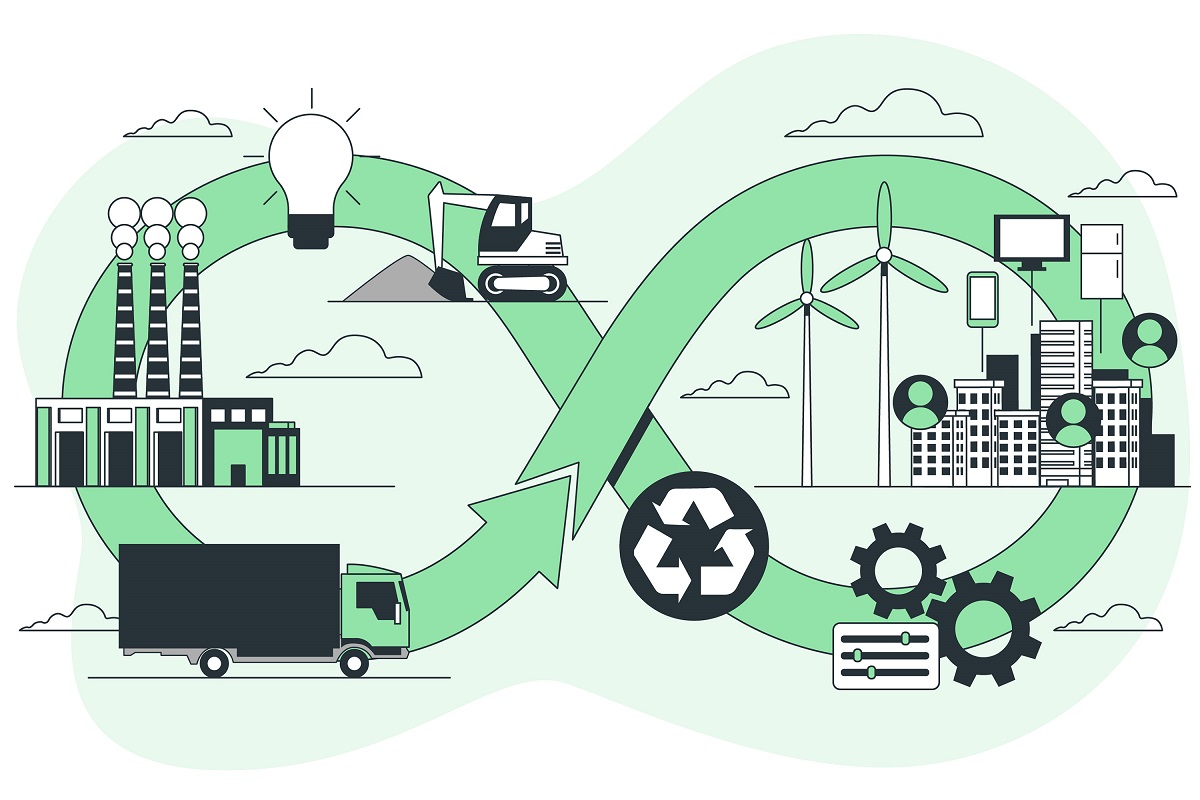

The linear “take-make-dispose” model of traditional manufacturing is reaching its breaking point. As environmental concerns escalate and resources dwindle, the focus is shifting towards a more sustainable future – one where zero waste manufacturing takes center stage. This exciting paradigm shift is fueled by the powerful combination of Industry 4.0 technologies and innovative circular economy principles. So, let’s delve into the future of manufacturing, exploring the trends and opportunities that pave the way for a clean and prosperous tomorrow.

The Problem: Mountains of Waste and Unsustainable Practices

Manufacturing, despite its undeniable economic contributions, carries a hefty environmental burden. According to the World Bank, the municipal solid waste sector accounted for over 2.01 billion tonnes of global waste generation in 2023. This represents a footprint of 0.74 kilograms per person per day. This includes everything from industrial byproducts and scrap materials to packaging waste and end-of-life products. These staggering numbers highlight the urgent need for transformation.

The Solution: Embracing Zero Waste Principles

Zero waste manufacturing, as the name suggests, aims to eliminate waste generation within the entire production lifecycle. This requires a holistic approach that encompasses:

- Resource optimization: Utilizing resources efficiently, minimizing inputs and maximizing product yield.

- Material substitution: Replacing virgin materials with sustainable alternatives like recycled content or bio-based materials.

- Design for disassembly: Creating products that can be easily dismantled and repurposed, extending their lifespan.

- Closed-loop systems: Establishing efficient recovery and recycling mechanisms for end-of-life products and materials.

Industry 4.0: The Technological Enabler

Fortunately, the rise of Industry 4.0 technologies provides the tools needed to translate these principles into reality. These interconnected intelligent systems offer unprecedented potential for:

- Real-time data analytics: Optimizing processes, predicting equipment failures, and minimizing material waste through advanced data analysis.

- Digital twins: Creating virtual replicas of physical production lines, enabling simulations and testing to design waste-free processes beforehand.

- Advanced robotics and automation: Leveraging robots for precise material handling, reducing human error and minimizing scrap generation.

- Additive manufacturing (3D printing): Building products layer-by-layer with minimal waste compared to traditional subtractive manufacturing techniques.

- Artificial intelligence (AI) and machine learning (ML): Utilizing AI for intelligent process control, predictive maintenance, and optimizing resource utilization across the entire supply chain.

Emerging Trends and Exciting Opportunities

The integration of these technologies is already yielding fascinating advancements:

- Smart factories: Connected, data-driven factories that dynamically adjust production based on real-time needs, minimizing waste and maximizing resource efficiency.

- Circular economy platforms: Online platforms facilitating collaboration between manufacturers, recyclers, and consumers, promoting resource sharing and product lifecycle extension.

- Blockchain technology: Enabling secure and transparent tracking of materials throughout the supply chain, ensuring responsible sourcing and facilitating end-of-life product recovery.

Benefits Beyond Sustainability: A Winning Proposition

Adopting zero waste manufacturing with Industry 4.0 technologies isn’t just an environmental imperative; it’s also a smart business decision. Benefits include:

- Cost reduction: Lowering material consumption, streamlining processes, and reducing waste disposal costs.

- Increased efficiency: Optimizing production lines, minimizing downtime, and maximizing resource utilization.

- Enhanced brand reputation: Demonstrating environmental leadership and attracting eco-conscious consumers.

- Innovation opportunities: Developing new sustainable products and services, unlocking new markets and revenue streams.

Challenges and the Road Ahead

Despite the promise, challenges remain:

- High initial investment costs: Implementing advanced technologies requires significant upfront investment.

- Lack of skilled workforce: Transitioning to smart manufacturing necessitates training and upskilling the workforce.

- Data security concerns: Integrating connected systems demands robust cybersecurity measures.

- Collaboration across the supply chain: Effective implementation requires cooperation between manufacturers, suppliers, and recyclers.

Specific Examples:

- BMW’s “Project Airframe”: Utilizes AI and 3D printing to minimize waste in aircraft wing production, reducing scrap material by 40%.

- Dell’s “Circular Advantage”: Offers refurbished and recycled electronics, aiming to recover millions of pounds of materials annually.

- Siemens’ “Closed Loop Initiative”: Partners with recyclers to develop innovative closed-loop supply chains for critical materials like rare earth elements.

Case Studies:

- Adidas’ Futurecraft.Loop shoe: Made entirely from recycled and recyclable materials, demonstrating the viability of circular product design.

- Tesla’s Giga Berlin factory: A showcase of smart manufacturing principles, featuring AI-powered production lines and energy-efficient processes.

- Interface’s “Net Effect” initiative: Offers carbon-neutral flooring products, highlighting the integration of sustainability into core business models.

Industry-Specific Insights:

- Textile industry: Utilizing bio-based materials like hemp and digitally optimizing dyeing processes to reduce water usage.

- Food industry: Implementing AI-powered waste reduction systems and exploring vertical farming for localized, resource-efficient production.

- Electronics industry: Designing for disassembly and developing efficient e-waste recycling infrastructure.

Conclusion: A Sustainable Future within Reach

The future of manufacturing is undoubtedly green. Though challenges exist, the combined power of Industry 4.0 technologies and zero waste principles presents an unprecedented opportunity. By embracing innovation, collaboration, and a commitment to sustainability, we can pave the way for a future where manufacturing thrives in harmony with our planet. It’s time to shift gears, leverage the power of technology, and embrace a circular economy. The future of a clean and prosperous manufacturing industry is within reach, and it’s a future worth building together.

Remember, this is just a starting point. You can further personalize this blog post by adding specific examples, case studies, or industry-specific insights relevant to your target audience. Additionally, consider including calls to action to encourage readers to learn more or get involved in zero waste manufacturing initiatives.

FAQs:

What is zero waste manufacturing?

Zero waste manufacturing aims to eliminate waste generation throughout the entire production lifecycle, from resource extraction to product end-of-life. This involves optimizing resource use, using sustainable materials, designing for disassembly, and implementing closed-loop systems.

How can Industry 4.0 technologies help achieve zero waste?

These technologies offer tools like data analytics, AI, robotics, and 3D printing to optimize processes, minimize waste, and track materials through the supply chain. They enable real-time monitoring, predictive maintenance, and precise resource allocation.

What are the benefits of zero waste manufacturing?

It reduces environmental impact, lowers costs through less waste disposal and resource optimization, enhances brand reputation, and opens doors to new markets and revenue streams from sustainable products and services.

What are the challenges to adopting zero waste practices?

High initial investment costs, lack of skilled workforce, data security concerns, and the need for collaboration across the supply chain are some key hurdles.

What role do regulations play in promoting zero waste?

Government policies like Extended Producer Responsibility (EPR), landfill bans, and carbon pricing encourage responsible practices and innovation. However, navigating different regulations and finding the right balance is crucial.

How can consumers influence zero waste manufacturing?

By choosing sustainable products, demanding transparency, and supporting companies committed to responsible practices, consumers send a powerful market signal and drive change.

What can I do to support zero waste initiatives?

Research and support companies with strong sustainability practices, advocate for effective regulations, educate yourself and others about responsible consumption, and share relevant resources and initiatives.

Is zero waste manufacturing a realistic goal?

While reaching absolute zero waste might be challenging, continuous improvement and striving towards this goal can significantly reduce waste and create a more sustainable future.